|

| November 14, 2017 | Volume 13 Issue 42 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

New type of corrosion protection for galvanized steel is self-healing

Chemcoaters, a leading coil coater and manufacturer of proprietary coating chemistries, recently introduced InterCoat® ChemGuard, a new type of corrosion protection for galvanized steel.

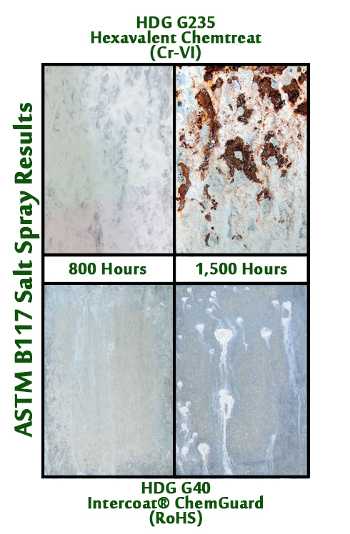

G235 treated with Hexavalent Chemtreat (top) vs. G40 treated with InterCoat® ChemGuard (bottom). Test: ASTM B117 salt spray test on hot-dipped galvanized.

InterCoat® ChemGuard features a new kind of coating technology that utilizes covalent bonds to enhance the effectiveness of zinc and substantially improve corrosion protection on galvanized steel.

The standard practice to protect metal from corrosion for the last 70 years has been to coat it with zinc. Heavier zinc coatings have normally been applied to provide longer protection. But InterCoat® ChemGuard, instead, is applied over a light layer of zinc, which reacts with the zinc to dramatically improve its corrosion-protection properties. When it reacts with the zinc, it forms a permanent, covalent bond on the surface of the metal. The bond that is formed at the molecular level cannot be washed or worn off. This is different and more effective than the typical barrier coating.

InterCoat® ChemGuard is a major development for any user looking to extend the corrosion resistance of galvanized steel. The revolutionary process allows bending, stamping, post-painting, and even shearing, while providing self-healing characteristics that help protect newly exposed zinc that naturally occurs during secondary processing. The product is RoHS compliant and is weldable. With a low coefficient of friction, it actually enhances these processes. It is designed to be applied on the galvanize line or, for custom formulas, by the original coil coater and developer of this unique compound.

G40 bare (left) after 144 hours and G40 with InterCoat® ChemGuard (right) after 2,520 hours. Test: ASTM B117 salt spray.

The product also offers significant cost savings, because it allows for lighter zinc to form the bond; it reduces the need for zinc coatings heavier than G30 in many applications on the market today. The product also eliminates the need for temporary corrosion-protection coatings, often used in shipping and materials storage, including hexavalent chrome, a known carcinogen. This makes it more environmentally friendly for all building, architectural, transportation, and consumer appliance applications.

It is applicable to many industries, including automotive, aerospace, construction, electrical conduit, wall studs, furniture, fixtures, appliances, outdoor and highway railing, agricultural, lawn and garden, and other products using galvanize.

For more information on this product, please visit the website at www.lowerzinc.com.

To discuss, or arrange a trial, please contact:

Bill Capizzano, President

Chemcoaters, Inc.

700 Chase Street

Gary, IN 46404

Email: billc@chemcoaters.com

Phone: 219-977-1929

or

Mike Tieri, Vice President, Sales & Marketing

Email: MikeT@chemcoaters.com

Phone: 708-715-7759

Published November 2017

Rate this article

View our terms of use and privacy policy